NATURE, HEALTH, ENVIRONMENTAL HOUSE

Wall panels are produced from ecological OSB plates coated with plasterboard boards. Also, as the insulating material, natural mineral wool and styrofoam are used, which are excellent natural, thermal and sound insulation.

SHORT PERIOD OF CONSTRUCTION

Since all mounting elements are made in

Our firm, the time it takes to build a house is in fact time needed for

assembly of finished elements, i.e. 3 to 7 days.

EASY CONSTRUCTION

ENERGY SAVING

FIXED PRICE (INCREASE) AND MANY COSTS MAINTENANCE

WALL ELEMENTS

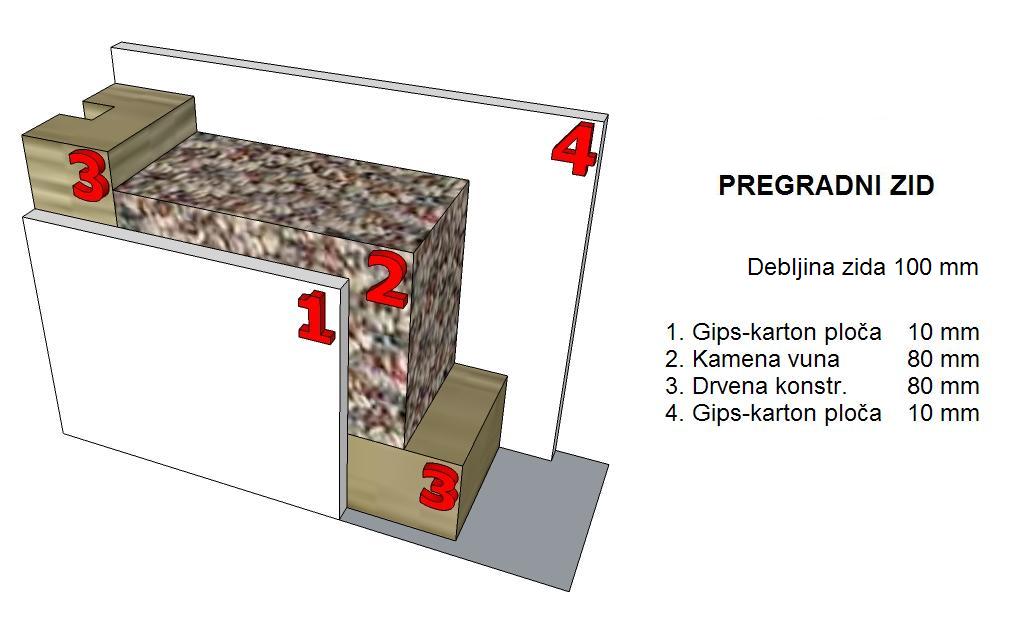

We distinguish the partition or façade wall elements of assembly houses.

According to customer’s wish, each element can be with or without built-in carpentry.

In order to optimize the assembly process itself, the wall elements of the typical assembly houses are made in our workshop in modular dimensions, allowing a short installation time for a few days to get a mounted object.

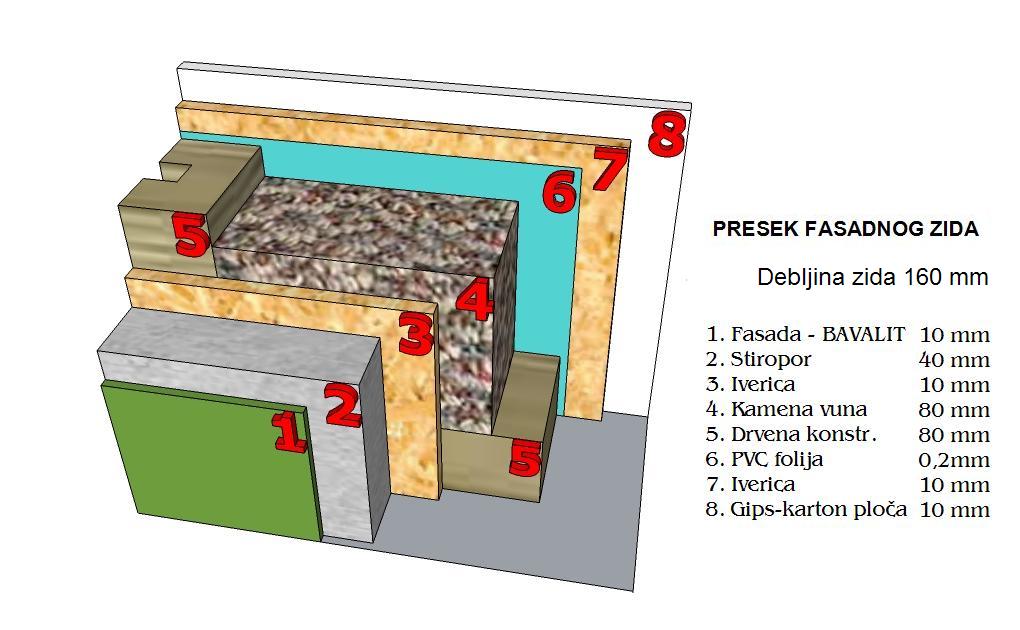

The facade wall differs according to the type and thickness of the outer lining, materials with proven and proven good isolation properties are used.

The construction of the elements is made of a wooden ram that is coated with the chipboard.

Stone wool and PVC foil are embedded between.

After the installation of the buildings, the facade walls are to be covered with construction styrofoam, masonry and priming of the curved façade.

On the inside, the walls are covered with a gypsum board.

The walls of sanitary rooms and kitchens are covered with waterproof gypsum board boards.

Prism of the wall construction looks like

like this:

INSTALLATION OF THE ELEMENTS

All elements such as wooden foundations are made of millimeter precision, assembly of elements and assembly in one whole is performed easily and quickly.

Wooden elements are protected from deterioration and moisture.

Condor is placed underneath all wall elements or foundations.

When fabricating, a wall-mounted currents are installed in the wall elements (electricity is not indented).

JOINERY

Balcony doors and windows are single, single-screen, open around the vertical axle, with the exception of a 60×60 cm window that opens around both axles with tilt-sloping joints. As part of the window and balcony doors, the shutters with movable gates are used. The joinery is wooden, but there is a possibility of installing PVC or Aluminum joinery. The type of carpentry as well as its dimensions are precisely defined when signing the contract.

The entrance door is secured with a lock lock with the lock, and the other door with locks.

All the carpenters are colored with color satin according to the buyer’s wishes.

FRAME CONSTRUCTION

Thick-walled panels are provided with a steel sheet, longitudinal and transversal slats of 24×48 mm, which is provided by the roofing underneath the roof covering. The calcareous sections are coated with a chipboard, overlaid by styrofoam and facade. Below the lower bonnet of the roof supports is a ceiling grille of 40×48, overlaid with PVC foil. and the gypsum board.With the upper side is placed mineral wool 80mm. The ropes of the roof are covered with a boat’s dotted planks, and the sheaves are profiled with a lampholder over the 40×48 mm cross-section. Boats and shelves are painted in color by the customer’s wishes.

Covering the roof is done with a standard crepe M 222. There is a possibility of installing some other coverings such as roofs (in four colors), tiles, hollows as well as other covers depending on the needs and wishes of Customers.

PLAFONIC CONSTRUCTION

The ceiling structure of the prefabricated houses consists of barbecue, insulation, steam dam and ceiling coverings.

TIN WORKS

Limarine works are mandatory in all our homes. Stoppers should be made of different materials, such as plain sheet metal, copper and fiberglass, and everything is fine when signing the contract. Our standard are round-bottomed flashes.

CHIMNEY

When signing the contract, we specify the manner and type of walling, ie whether it will be masonry with ordinary bricks or shamed elements (Šidel Funnel)

THE FLOOR

The standard floor that is built into the houses that the company is making is laminate. When the laminate is installed, it is possible for the Buyer to choose the color and pattern. In addition to the laminate there is the possibility of installing a ship’s floor, parquet. Also, the possibility of more precise choices was left.

INSTALLATION

The electrical installation is being done during construction, and the entire installation is drained through the throat hose.

CERAMICS

The company builds high-quality ceramics of domestic manufacturers (by arrangement and foreign). As for the way of installation, the bathroom is covered with all four side tiles plus a floor, while in the kitchen, all four sides of the wall are covered, but unlike the bathroom, the height at which it is installed does not exceed 1.50m. Except in the bathroom and kitchen, there is the possibility of installing tiles in other rooms, in accordance with the requirements and needs of the Buyer.

Pogledajte cene

Kalkulator za okvirnu cenu brvnara